Transforming plant operations with immersive Industrial AI

Reduce emissions, accelerate sustainability, drive more productivity with the powerful 1-2 punch of intelligent AI and immersive 3D.

Connect with us to learn how plant operators around the globe are solving complex problems with our innovative technology.

Connect with us to learn how plant operators around the globe are solving complex problems with our innovative technology.

Reduce costs, risk, and your carbon footprint–all at once

We are excited about the impact V-Suite provides the C-Suite in terms of accelerated compliance with 2030 sustainability goals.

Vikas Agrawal

CEO, Visionaize

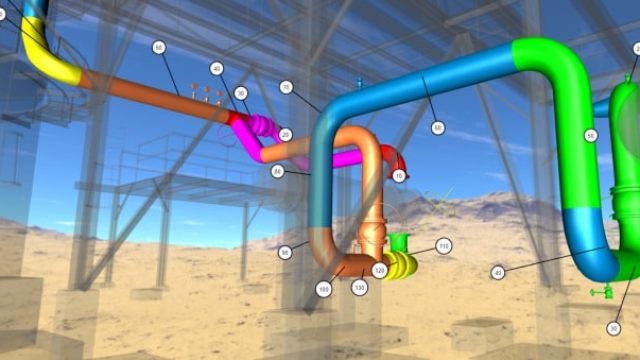

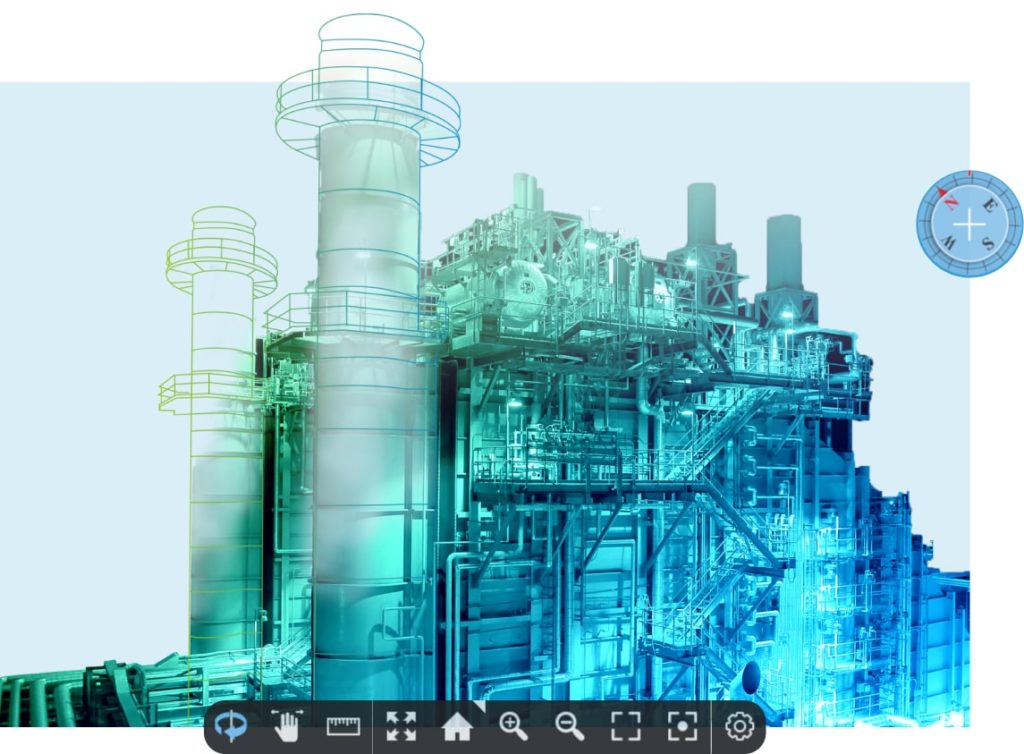

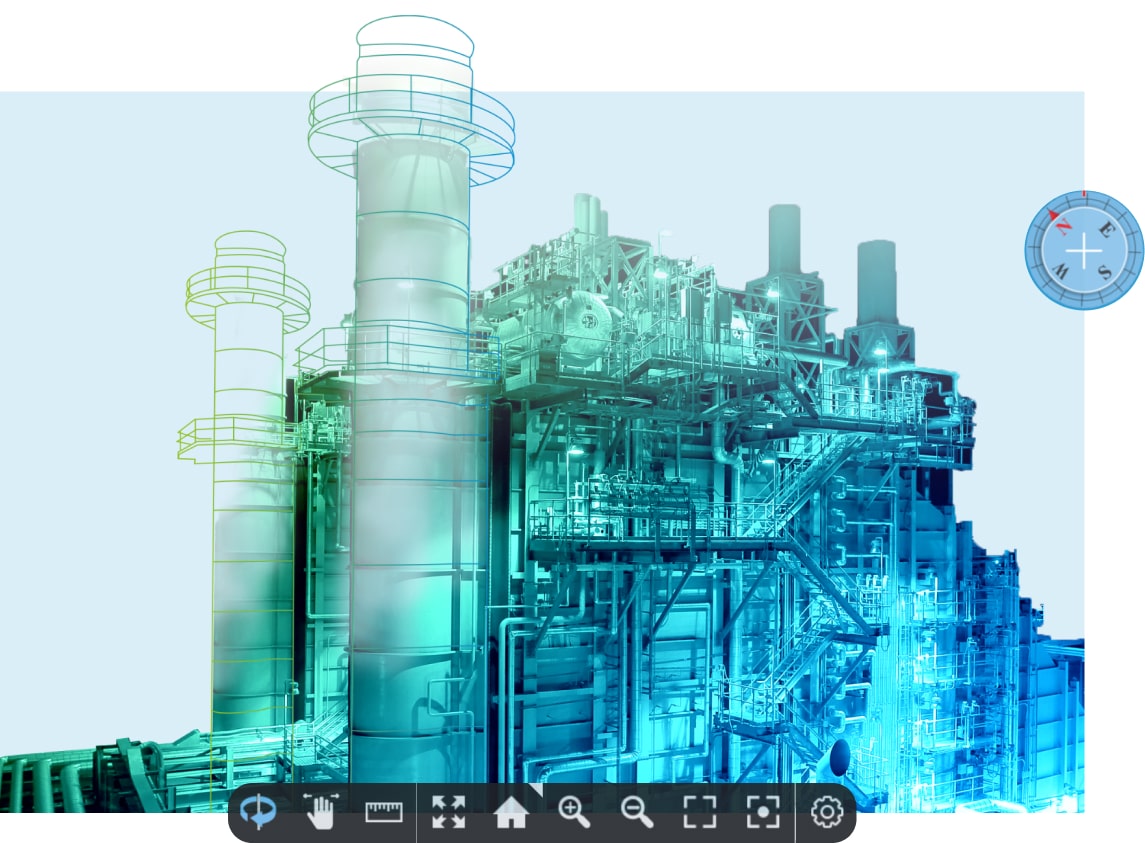

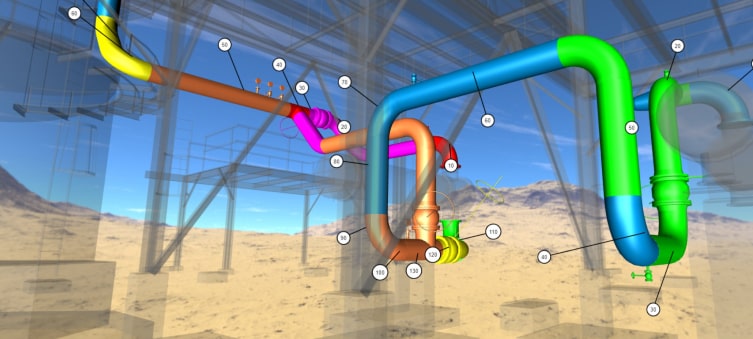

The truly operational digital twin

Up-to-date 24/7/365, built from the ground up as a fully operational Digital Twin

The most robust integrations with enterprise systems of record and 3D modeling platforms

Role-based, customized work packages to improve productivity and worker safety

Immersive 3D Enterprise Asset Management (EAM) experience with AR and VR capabilities

Turnarounds that reduce costs by more than 10%

A collaboration between PwC and Visionaize, this Whitepaper delves deeply into a modern approach to Turnarounds that enables operators to maximize productivity and significantly reduce downtime.