Process Performance Prediction (PPP)

Process upsets such as abnormal heater coking, catalyst higher degradation, absorber or column foaming/ flooding, off-spec product quality, are critical issues in any process plant. Operators often get to know them when it’s too late to avoid production loss and shutdowns.

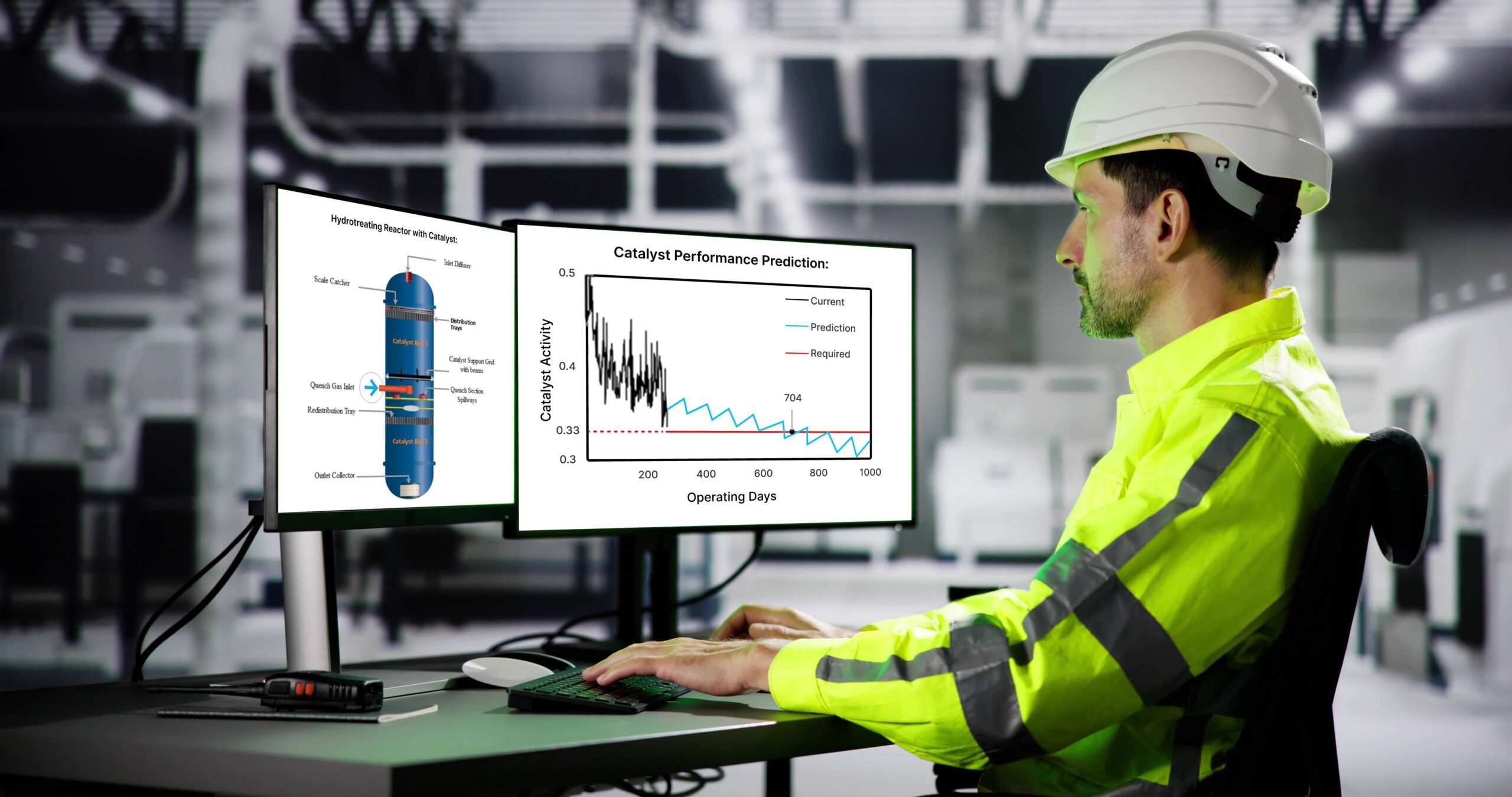

Combining industry expertise with cutting edge AI and GenAI technologies, the Visionaize team has developed solutions to not only predict upsets early, and minimize production loss and shutdowns, but avoid them altogether.

Connect with a solution specialist to learn more about how to cut out the downtime.