Predictive Maintenance (PdM)

Over time equipment’s performance and health get affected because of mechanical wear & tear and the impact of upstream operations. When these problems are not detected early enough, costly shutdowns can occur, as a result.

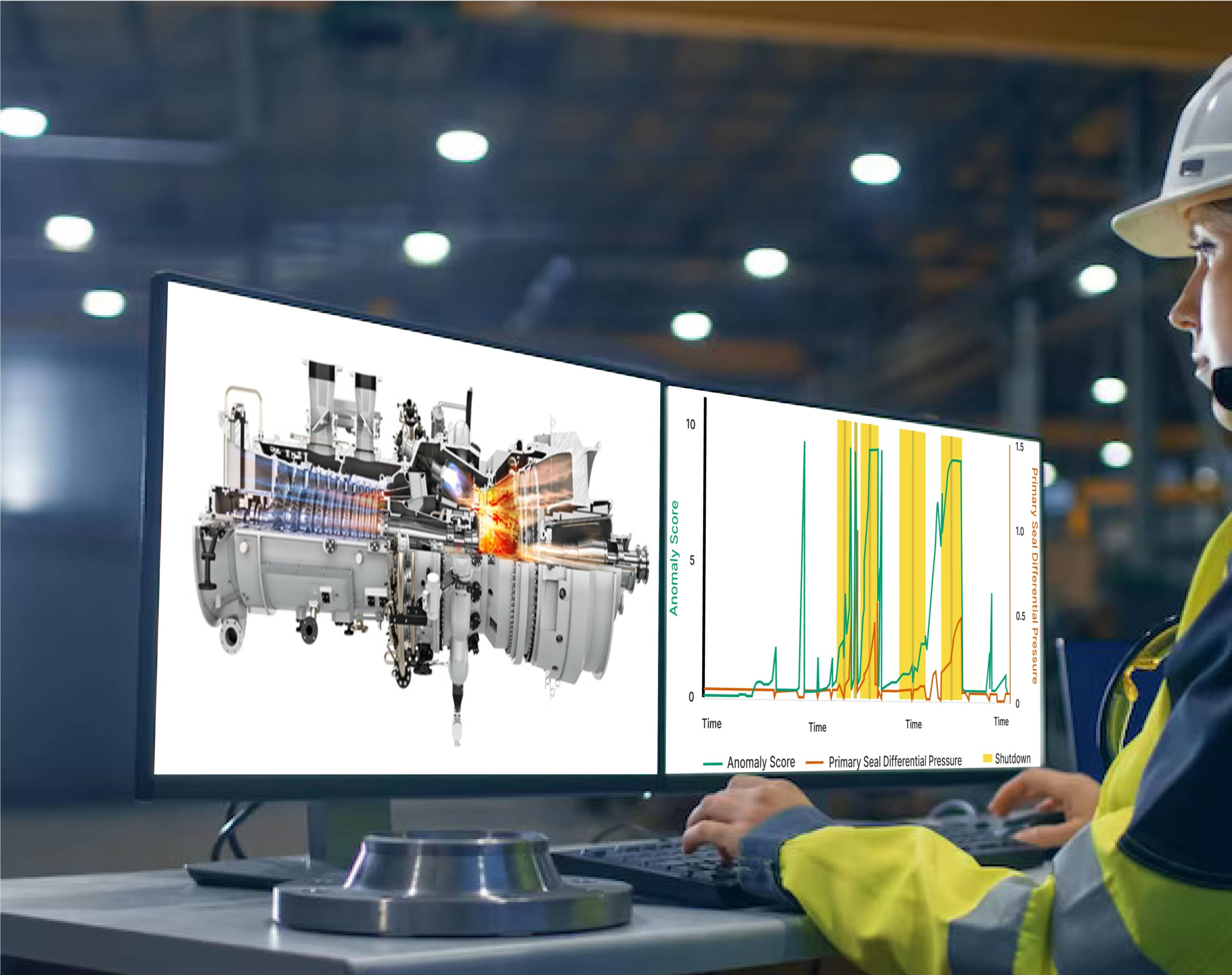

With Visionaize’s Predictive Maintenance solution, facility owners have the tools to detect anomalies, diagnose the root causes and take corrective actions early enough to avoid unplanned shutdowns.

Request a demo to see how it works.