GE Digital & Visionaize Partnership – Combining APM with Contextual 3D Visualization

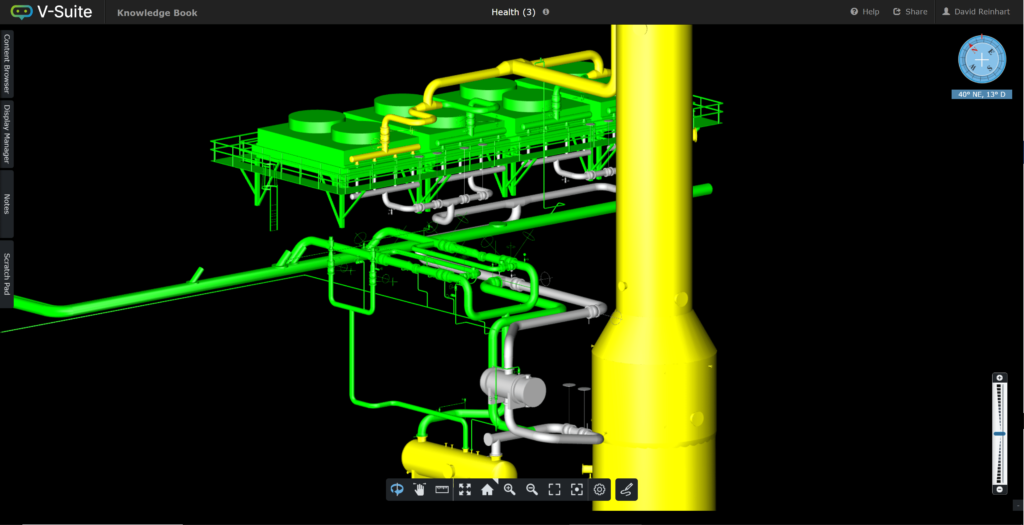

Visionaize, the provider of world-class operational 3D digital twins solutions, announced a partnership with GE Digital. 3D Digital Twins’ high accuracy visualization capabilities are designed to help empower data-driven businesses and improve safety by saving time and reducing cost throughout asset intensive industries across all sectors where they’re used. The V-Suite Starter by Visionaize can be integrated into GE Digital’s APM (Asset Performance Management) Mechanical Integrity™ software to help streamline maintenance activities while increasing worker efficiency.

With V-Suite Starter, industrial companies can view real time and historical asset data on the 3D model to deliver timely insights at their points of action. The “see it happen” visualizations will help them solve key challenges associated with downtime such as quicker resolution times for maintenance costs or workforce productivity improvements by providing a better understanding about what is happening in an equipment room before problems arise so they are prepared accordingly. The product allows you to see your investments more clearly through 360 degree views which helps reduce risk.

“As companies in asset-centric industries — Oil &Gas, Power Generation, Petrochemical, and Mining — look to enhance their digital transformation journey, there is a growing acceptance to absorb Digital Twins into their operational decision-making workflows,” said David Reinhart, Executive Vice President for Visionaize. “To build out a more robust Digital Twin experience, there is a pressing need for rapid contextual awareness and visualization capabilities.”

Visionaize helps mechanical engineers and industrial designers visualize 3D plant models with APM’s integrity attributes in order to make data-driven decisions. The integrated solution not only provides insights, but also enables users by color coding the model so they can focus on what matters most when it comes down to their job responsibilities of inspection, planning, maintenance, corrosion analysis and Risk Based Inspection.

With GE Digital’s APM solution, workers can be safer and more productive with a better understanding of the environment around them. Accurate 3D models allow for faster resolution time as well as maintenance programs that are optimized to speed up planned downtime activities while accelerating unplanned events too.

“Our partnership with Visionaize brings an enhanced scalable templated capability to APM that accelerates implementation and simplifies replication across sites and reduces implementation costs,” said Linda Rae, General Manager of GE Digital’s Power Generation and Oil & Gas business. “Incorporating this state-of-the-art visualization platform is valuable as asset-intensive companies mature in their operational use of Digital Twins.”

Click on these links for more information about Visionaize’s Digital Twin Asset Performance Management Software and solutions for Manufacturing, Oil & Gas, or Power & Energy.