How Digital Twin Technology is Transforming Supply Chains

Digital Twins in the Supply Chain

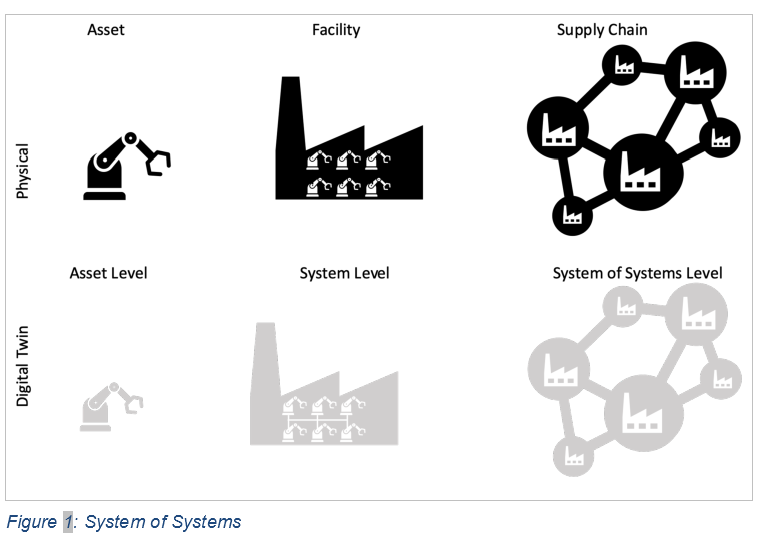

When you think of digital twin technology, the first thing that comes to mind may be a large, industrial asset, such as a power generator. And you would be correct — a digital twin is most often a digitized replica of a physical asset, or set of assets, with a 3-Dimensional visual view of it. The model includes real time data from sensors that measure and monitor the behavior and state of the physical asset(s) the sensors are attached to. It also has the ability to keep itself in sync with changes to the assets over time. This living, learning digital twin provides many advantages in industrial and manufacturing industries that have been covered in “The Importance of True-to-Life 3D Digital Twins“. Digital twins at the asset level, at the facility level (multiple assets, connected in systems), are most common today. But digital twin technology can also be used to systems of interconnected facilities, that can help manage, visualize, and monitor complex systems, including supply chains.

This system of systems approach, depicted in Figure 1, is an emerging approach for organizing and integrating supply chain monitoring and prediction, being labelled a Supply Chain Digital Twin.

What is a Supply Chain Digital Twin?

Today’s supply chain managers are working in an incredibly fast-paced environment. Many global factors have contributed to unprecedented pressure on modern supply chains. Successfully managing these complicated systems demands that decision-makers have real-time data and insight into what is happening at any given point in the entire supply chain continuum. The ability to forecast multiple outcomes from any number of hypothetical “if-then” decisions is also imperative for supply chain managers to make the best decisions possible. What is being referred to as a supply chain digital twin, is a combination of advanced analytics (or Artificial Intelligence), data visualization, and 3D Visualization technology, implemented in concert to meet each of these critical needs.

A supply chain digital twin is one that is implemented at the System of Systems level, to provide a highly detailed, dynamic simulation of supply chain performance from start to finish, with the added benefit of being able to “zoom in” to the individual nodes in the network, where visualizing the systems of assets can be used to aid operations, monitor remotely, and allow workers to do more remotely. Powered by AI technology and highly advanced analytics, these digital twins process, manage, and visualize tremendous amounts of data — from what is happening supply network-wide, what is going on at the individual facility level, down to the exact location of a specific shipping container and for sophisticated organizations, even the contents of the shipping container. This capability offers supply chain managers an extremely detailed report of the current state of their operation. They also serve decision-makers with the ability to understand data in context, run many more number of predictive scenarios, and benefit from live data visibility in real-time.

Advantages of a Digital Twin in Supply Chain Management

For the supply chain manager, a digital twin system of systems can quickly become the most valuable member of the team for many reasons. The digital twin interface allows managers to see what is happening across multiple points and processes in a supply chain in real-time. It can call out potential disruptions or delays before they happen and intelligently predict the best solution with its advanced AI capabilities, allowing users to meet their goals even in today’s turbulent market and global supply chain environment. Digital twins can be programmed to monitor a company’s desired KPIs and suggest adjustments in real-time to avoid costly mistakes and keep performance on track. The remote visual monitoring capabilities allow operations to be planned, executed, and monitored with more safety, accuracy, and efficiency because complex plans can be simulated and observed without physically having to be on-site. Supply chain digital twins are designed to create a clear path to the most efficient and profitable course of action for companies under an infinite number of possible challenges or circumstances.

The Future of Digital Twins in the Supply Chain

The issues impacting the global supply chain make digital twins more important than ever in supply chain management. As observed by Nexxiot, using “…a digital twin, companies can test predicted supply chain shifts and bridge weaknesses before they occur in the real-world.. No surprise then that “…62% of businesses plan to implement digital twin technology in the coming years.” (Gartner)

A digital twin’s ability to make the reams of supply chain information coming from so many systems more usable and more understandable makes them a useful tool in preventing supply chain disruptions and breakages before they occur, as well as making supply chain operations safer and more predictable. More and more supply chain managers are taking notice. With ever-developing advances in AI technology and the optimization of digital twin integration throughout the supply chain, the future of digital twins in supply chain management is dynamic and exciting. V-Suite, designed to be the most connected and intelligent digital twin on the market, is on the cutting-edge of these exciting advances.